|

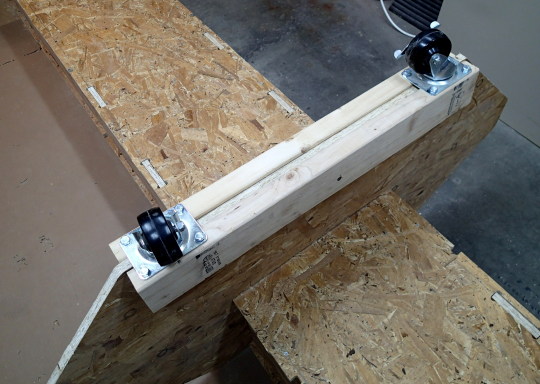

| Ear of the Sternberg Chair |

Okay, don't be alarmed by this picture. It continues to be a blog about Sailboat Building. For reasons which no longer make all that much sense, I had started a separate blog for my

kayak building efforts. For now I'll keep it that way.

So let me explain the connection between this picture and boat building. ~ Bear with me: this entry will be a bit wordy. Sorry!

I have not added to this blog in quite a while and the casual visitor might have surmised that with my Passagemaker Dinghy

C-Lute sold (to a wonderful sailor in Atlanta), this might be the end of it.

Well, NO. To begin with, the reason I decided to part with

C-Lute was my desire to build a new sailboat though I did not yet know what kind. With three wooden kayaks and one wooden sailboat (plus a modern racing dinghy) I really could not justify building another sailboat without first creating a "sailboat vacuum" to make space for a new build.

So, instead of another "winter building project" I allotted time this previous winter to researching what my next sailboat build might or should be. I knew that I wanted something heftier and bigger so long as I could still fit the construction process into my garage. It was not going to be a S&G (stitch & glue) boat like

C-Lute because I hoped to try a different building method called

glued lapstrake.

My criteria: I wanted a versatile boat, one that could be used for single-handed day-sailing, for the learn-to-sail program (where I volunteer as a certified instructor), for camping cruising the Chesapeake, for a comfortable romp in blustery conditions and for an easy transition to row when the winds die: essentially an open

sail and oar boat with plenty of canvas to move on a wisp of air yet easy to reef or dowse and a pleasure to row. There are many boats by well-known designers to fit in this category. Space constraints eliminated many attractive options such as the

wonderful Iain Oughtred designed double-enders like the Ness Yawl,

Caledonia Yawl and Sooty Tern... all in the 19' range. 14 - 15 feet were probably going to be the maximum hull length over all.

|

| Ilur - Lug / Sloop Rigged |

After reading a number of boat building books (including Iain Oughtred's "Clinker Plywood Boatbuilding Manual") I did indeed resolved to build a clinker boat better known in US parlance as glued-lapstrake. In the days before the modern materials this construction method involved rivets and a very complex set of work processes not at the disposal of someone without specific training. Nowadays lapstrake boats can be constructed using modern material (epoxy, fiber glass and marine plywood) to build a very traditional-looking hull at a fraction of the cost and time - not to mention without the essential and exquisite skills of an experienced ship-wright (to do a half-way decent job). Epoxy and marine plywood make boat construction readily accessible to a hobby-builder.

Countless building blogs and boat building sources (such as the Woodenboat Forum) were consulted as I clawed myself to a decision.

Actually, I was hoping to be found by a design rather then the other way around.

And then there was an article in the Wooden Boat Magazine (2015 Small Boat Edition) by Geoff Kerr (

Two Daughter's Boatworks) about a boat called

Ilur designed by

French Naval Architect Francois Vivier that seriously piqued my interest. As it turned out, the builder of the reviewed Ilur (John Hartman) had an extensive and extremely informative thread on the

Wooden Boat Forum where I could read blow-by-blow what was involved in building an Ilur.

I then downloaded a study plan on building an Ilur and came to grips with the realization that this was going to be A LOT MORE involved than any of my previous building projects BUT that even so, the unique design of this plywood clinker kit was thought-out so ingeniously that it would take a builder a lot less time than some of the other builds I had been looking at. Clearly it was going to be a lot more than a winter project. Obviously I looked at the other Vivier boat designs as well. In the end, Ilur seemed to best fit

mon goût in terms of size, versatility, practical application, "provenance" and salty appearance.

|

| The Plans for Ilur |

The next step was to order the actual plans from Mr. Vivier who sent them promptly. I was extremely impressed with the extraordinary detail and clarity of the drawings.

I must mention another valuable resource that helped to muster my courage to do this build, namely the

Off Center Harbor video series, by Geoff Kerr on building a glued lapstrake Caledonia Yawl. I highly recommend this site to any lover of wooden boats regardless as to whether or not you want to build a boat yourself.

In the lapstrake building video course, Geoff Kerr recommends to prospective boat builders that they build themselves a "Manning

|

| Manning Bench - components separated |

Bench" (or two) the construction of which is described in a book called The Workbench Book (The Taunton Press).

After waiting for the ordered book for over six months (presumably out of print) it finally arrived and I was able to construct one of these modular workbenches.The two components (1' hi and 2' hi respectively) can be used separately or clamped together as a single 3' hi bench.

In combination with my other workbench, I'll be able to create a long platform for the building of spars.

|

| Manning Bench - components together |

As I learned more I became somewhat intimidated by the prospect and concluded that I first needed to acquire some experience in working with hard wood. This was clearly a needed skill and it required tools I had never owned or used before. Obviously, even the best tools are useless if you don't have the skill and experience to properly use them.

Last spring I had been in Germany after my mother passed away. Essentially this set back any considerations of commencing the project by many months. Furthermore a major software upgrade project at work was going to require all of my undivided attention for six months or more. So while these two matters caused a significant delay, it gave me time to ponder my plans and consider my angle of attack - from afar.

|

| Burg Sternberg |

My parents had inherited an unique chair, a good number of which had been build for my grandfather according to his design and specifications. My grandfather (a pioneer in Early Music) had established an instrument workshop and museum of rare historical instruments on Burg Sternberg where he offered seminars as well as workshops in construction and performance of Renaissance instruments. In the early 60's Burg Sternberg became well-known to Early Music lovers and was recognized for the extraordinary acoustical properties of the

Rittersaal. (see my blog entry

So That's Why) This is the hall for which these chairs were intended and where I first sat on one.

Anyway, this arm chair had a straight and austere form but its shape struck me almost as a throne of sorts on account of its generous width and the unique scrolled ears invoking the look of an early musical instrument . This

Sternberg Stuhl (as I began to call it) was surprisingly generous and comfortable almost luxurious - a perfect listening and thinking chair. I would have loved to take it with me across the ocean but that was not exactly practical. However I took lots of pictures and precise measurements. So now, as I had resolved to acquire some experience with hardwood, this particular design offered itself as an attractive and to-me meaningful opportunity.

I consulted with my dear friend Garth Jones (who is a

professional builder of exquisite custom-designed furniture as well as a boat builder) regarding the optimum wood of choice: it was determined to be Cherry.

|

| One of these chairs will soon go to a new home |

Before trying my hand (and tools) on Cherry I wanted to make sure that I had not gotten confused with the (metric) dimensions. Therefore I picked up some construction lumber and fashioned a somewhat crude version of the chair simply to make sure that the dimensions "felt right". They did and off I went to buy enough fine Cherry for two

Sternberg chairs... just figuring out what and how much I needed without unnecessary waste was a new skill.

The chairs have been finished off with several silky coats of Danish Oil and now have that wonderful variegated Cherry glow which over time will darken. With the support of and guidance by Garth Jones, I learned quite a bit about working with hard wood and am now "pronounced to be ready - for the most part" to commence Ilur.

The kit has been ordered and cut by Hewes & Co.

In fact, it is being shipped as I write this.

Ah - anticipation is such a sweet thing!