I had it shipped to a nearby warehouse from where a friend helped me with his pickup truck to transport all 750 lbs. to my garage.

The sheets of plywood arrived on a 4' x 8' wooden pallet.

Just bringing this package home and unloading it sheet by sheet proved to be quite an undertaking.

Happily, all arrived in perfect order.

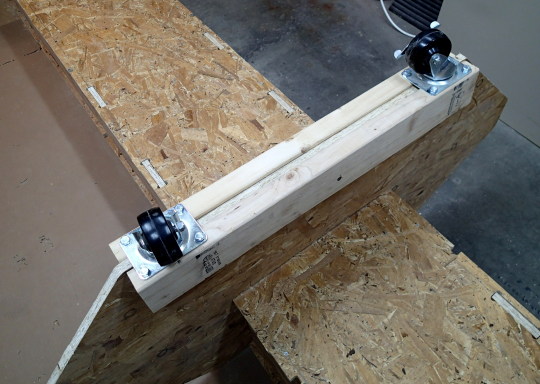

The ingenious and innovative aspect of the Francois Vivier boat kits is the fact that along with the plywood, you receive precisely cut AdvanTech boards with which you can assemble the strong-back and station forms.

The ingenious and innovative aspect of the Francois Vivier boat kits is the fact that along with the plywood, you receive precisely cut AdvanTech boards with which you can assemble the strong-back and station forms.Without a doubt, this saves the builder countless hours of preparation.

All the same, building an Ilur is a big project from my perspective and for my level of experience. (or lack thereof)

More immediately, I will be able to utilize the strong-back as a convenient platform for a number of preparatory tasks prior to setting up the station forms.

In reading through Vivier's plans I actually did not fully appreciate just how many steps of preparation are necessary.

The most immediate job is to find a good source for timber. This is proving to be trickier than I expected. If I lived in Washington State or Maine this would not be a problem but around here it is not so simple. Mars Lumber has a reasonable supply of domestic and exotic hard woods but when I drove up there with trailer in tow (in order to haul some long pieces) I struck out. I will probably have to schedule a trip to my friends at Chesapeake Light Craft in Annapolis who not only sell their boat kits and related supplies but also a great deal of generic marine lumber.

In the meantime, there is much preparatory work. The transom needs to be assembled and top piece carved.

The 40 strake pieces need to be glued together into a total of 20 full length planks - 10 for each side.

Alas when shopping for wood I'll have to be able to translate into feet and inches.

Then the center-board trunk needs to be fabricated.

Then the center-board trunk needs to be fabricated.This task is quite involved and requires consulting a number of different pages of the plans in order to determine all of the specs. It is particularly critical to get this right since this will be the last and only time you'll be able to work on the inside of the trunk. It's got to be rock solid and able to withstand the stress of wave action and the wear and tear of the up and down sliding of the center-board.

More about that next...